Danish Army

Specific: The army awarded the

Danish company A/S Hydrema a contract late 1996 to supply

the vehicles after an international competition and

trials.

The first four Hydrema 910 Mine Clearing Vehicle (MCV)

systems was handed over in DEC 1997 to the Danish Army,

with the remaining eight to follow early 1998. Additional

2 was acquired late 2001/early 2002.

Historical: The Hydrema 910 MCV builds on the

company's experience in design, development and

production of off road vehicles, mainly for the

construction industry, as well as its experience in

hydraulics. To reduce life cycle costs, proven and

in-production components have been used where possible.

The MCV is designed for rapid clearance of surface or

buried anti-tank mines which contain up to 10kg of high

explosive in military and peacekeeping operations.

In 2003 24 units of the improved 910MCV2, including

training and spare parts, have been sold to the Indian

armed forces.

Length: 8.50 (331 inches).

Width: 2.80 (109 inches).

Height: 2.70 m (105 inches).

Weight: 18.000 kg (39.600 lb.).

Armour: 14 mm.

Engine: 2 Perkins 1006-6TW 6-cylinder turbocharged

diesel engines.

Horsepower: 178 hp ea. at 2.600 rpm.

Transmission: Six-speed ZF 6WG150 semi-automatic

transmission/separate hydrostatic transmission.

Transfer case: None.

Electrical system: 2 x 24V.

Brakes: Dual circuit servo assisted with oil

immersed discs on all wheels.

Tyres: 17.5 - 25 non-directional with

foam filling.

Fording depth:

without preparation: N/A.

with deep water fording kit: N/A.

Fuel type: Diesel.

Fuel capacity: 300 liter (66 gallons).

Range: N/A.

Crew: 2.

Armament: None

Additional: The vehicle is based on an

articulated chassis so that all four wheels are in

contact with the ground at all times. When being driven

on roads, the cab is to the front; during mine clearing

operations, the vehicle is driven in reverse with the cab

to the rear. The fully-enclosed, all-welded steel armour

cab protects the occupants from small arms fire up to

7.62 mm armour piercing calibre and large bullet-proof

windows give all round visibility. For increased crew

comfort during travelling and mine clearing operations,

the cab is suspended in rubber elements. It seats three

people although the system is normally operated by a crew

of two.

The vehicle is powered by two Perkins 1006-6TW 6-cylinder

turbocharged diesel engines. One is used for driving the

vehicle and is coupled to a six-speed semi-automatic

transmission. The second diesel engine powers the mine

clearing flails. Each engine has its own cooling, air

filter, exhaust and hydraulic system. During mine

clearing operations, a separate hydrostatic transmission

is used which gives a continuously variable speed and

considerable tractive force. This hydrostatic driving

unit can be supplied from the hydraulic system of the

powerpack and can be used in an emergency should the main

engine stop, enabling the Hydrema 910 to move out of

immediate danger under its own power.

The MCV can be driven on roads up to a maximum speed of

35km/h. The vehicle is steered through a hydrostatic

pivot steering system on all four wheels with an

emergency backup in case of engine failure. The fuel

tanks hold 300 liters and these are integrated onto the

chassis for maximum protection. When travelling, the

complete flail system and deflector, which is suspended

on hydraulic systems, is raised clear of the ground and

traversed through 90° using a hydraulically operated

tilting/turning system so that it is in line with the

chassis. In this configuration, it can be driven on

public roads.

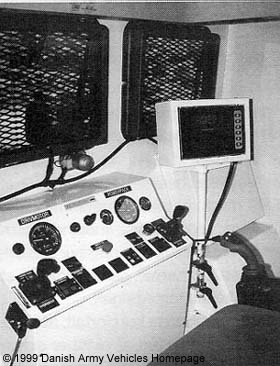

When required, the complete flail system is rapidly

lowered into position at the rear. The system can clear a

mine path 3.5m wide. During mine clearing, the vehicle

can be operated using a joystick or through the use of a

computerised fully automatic pilot steering system. When

being used in the latter configuration, the operator

needs only to select a number of key parameters, for

example depth, on the monitor. The depth control of the

flail and the armoured deflector plate, which is

positioned to the immediate rear of the rotating flail,

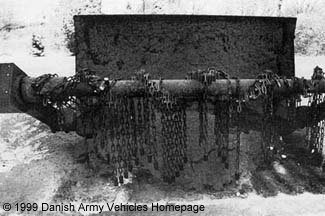

is then fully automatic using sensors. The chains rotate

clockwise if mines are buried and anti clockwise if they

are on the surface. The mine clearing part consists of a

rotating axle to which are attached 72 chains; the end of

each of these is fitted with a hammer type head which

weighs 0.9kg. When these chains or heads are damaged,

they can be easily and quickly replaced The axle rotates

at up to 400rpm, with the speed depending on the nature

of the terrain. Mine clearing speeds depend on a number

of factors. On cross-country terrain, for example, it is

about 1.4 km/in while on a firm hard surface it could be

up to 12km/h.

Standard equipment for the Hydrema 910 MCV includes a 200

liter water tank and high pressure cleaning system;

options include a Global Positioning System (GPS). As the

system may be required for operations in any part of the

world, it is fully air portable in a Lockheed Martin

C-130 Hercules transport aircraft without further

preparation, and can be ready to use within 2 minutes.

Jane's Defense Weekly December 1997

|